-

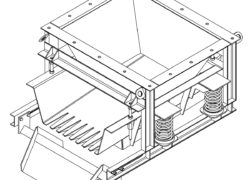

VST-Type Vibrating Screen-Chute with Sifter

Purpose (function): linear uniform feeding (transport) of the product (stone, coal, lime, etc.) from the collecting hoppers at any vehicle or dosing equipment (conveyor, feeder, bucket conveyer, etc.) of the process chain, as well as separation of fine fraction (up to 40 mm).

Operating principle: consists of a chute with a mounted sifter under the unloading part (wedge-shaped teeth with corners). Size of fractions sifted is adjusted through the longitudinal movement of the top of the sifter chute. The opposite side of the chute is restricted to a tailgate, to the wall of which two shakers are attached. When the vibration motor is on, the oscillations are transmitted from them to the chute and sifter, stimulating the longitudinal movement of the material (product) on the chute and separation of fine fraction via the sifter. To reduce the vibration loads, the chute is mounted on springs-absorbers. Device operating mode – cyclic/continuous.

-

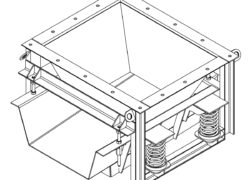

Vibrating Feeder — VFT-Type Chute

Purpose (function): linear uniform feeding (transport) of the product (stone, coal, lime, etc.) from the collecting hoppers at any vehicle or dosing equipment (conveyor, feeder, bucket conveyer, etc.) of the process chain.

Operating principle: vibrating feeder-chute by a flange at the top of receibing hopper is attached to a collecting hopper filled with material. When the vibration motor is on, discharge of material in the chute starts. To reduce the vibration loads, the chute is mounted on springs-absorbers. Device operating mode – cyclic/continuous.

-

FB-Type Feeder-Batcher

Purpose (function): weighing of an exact batch (portion) of the product capable of adjusting speed of product discharge from the hopper.

Operating principle: mounted on strain gauges, receiving hopper of the device allows weighing products coming into it. After product loading into the hopper, the device is immediately ready for subsequent discharging of a batch (portion). Vibrochute of feeder-batcher discharges a batch (portion) of the product with the help of two vibration motors. Vibration motors provide linear product displacement on the chute. The product discharge rate can be controlled through the unbalance of vibration motors’ eccentrics.